Application Of Gravity Separation In Beach Sand Beneficiation

Specific applications

(1) Separation of high-density minerals:

Gravity separators can accurately separate heavy minerals (such as ilmenite and zircon) from light minerals in seaside sand to ensure the effective recovery of target minerals.

(2) Multi-stage mineral processing:

Through multi-stage processes such as roughing, concentrating and scavenging, gravity separation equipment can maximize the enrichment of target minerals and improve the overall mineral processing efficiency.

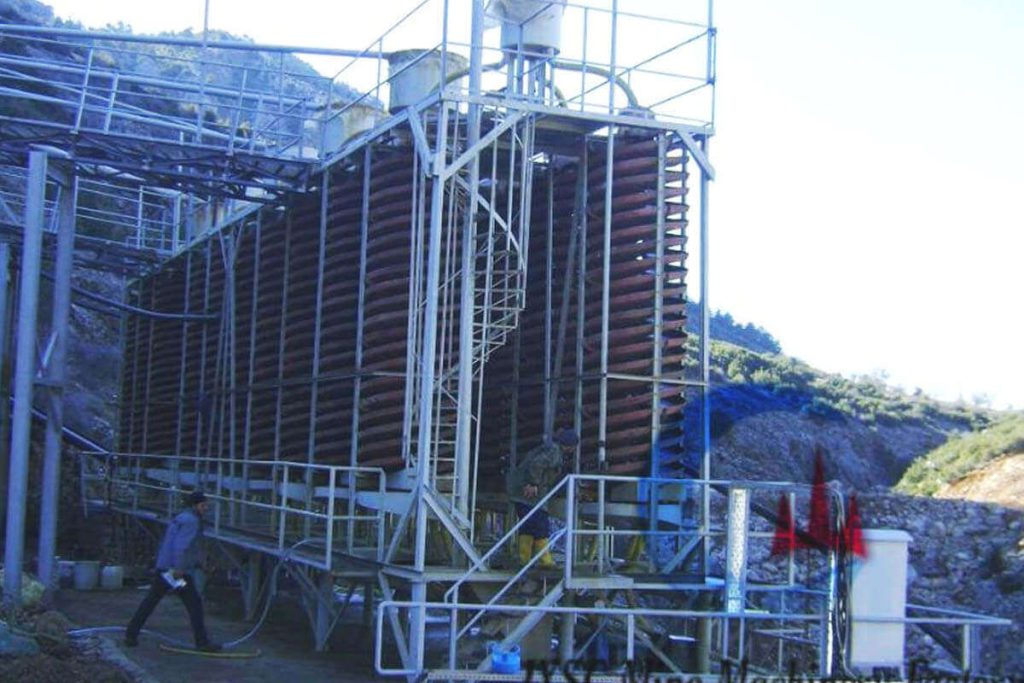

- Roughing stage: Use spiral concentrator for preliminary separation to remove most of the light minerals and obtain rough concentrate. Large processing capacity, low cost, and can quickly enrich heavy minerals.

- Concentration stage: Use shaking table to further separate the rough concentrate to obtain high-grade heavy mineral concentrate. High separation accuracy can effectively remove impurities and improve the purity of heavy minerals.

(3) Efficient utilization of resources:

The gravity separation process can effectively extract valuable minerals from seaside sand, reduce resource waste, and improve the comprehensive utilization level of resources.

(4) Environmental protection:

Gravity separation mainly relies on physical methods, without the use of chemical agents, reducing pollution to the environment, and meeting the requirements of green mineral processing and sustainable development.

Therefore, gravity separation plays the most critical role in seaside sand beneficiation, which not only improves the beneficiation efficiency and product quality, but also promotes the efficient utilization of resources and environmental protection.