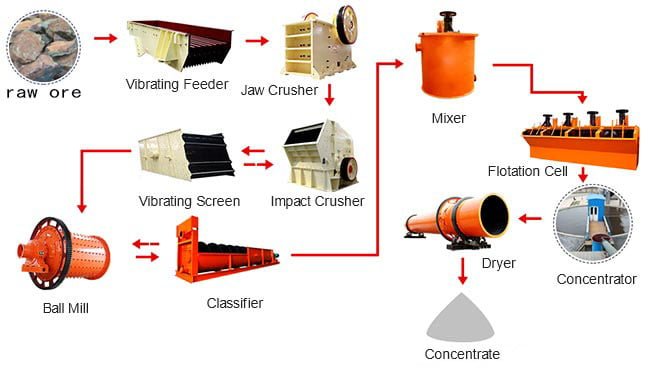

Copper Ore Processing Plants, Flow And Equipment

Preparation process before separation

Including copper ore crushing, screening, grinding, grading and other processes. The purpose of this process is to separate useful minerals from gangue mineral monomers, and to dissociate various useful minerals from each other

1. Crushing process

The copper ore that needs to be processed must first go through the crushing process. The vibrating feeder is fed through the silo, and the vibrating feeder is evenly sent to the jaw crusher for primary crushing, and the large raw ore is broken into small pieces of ore. After the coarse crushed copper ore is screened, it is sent to the cone crusher by the belt conveyor for intermediate crushing and fine crushing, and the ore is broken into smaller ore particles.

2. Grinding process

The copper ore processed into granules is screened by a vibrating sieve and sent to a ball mill for grinding and crushing. Here also need to use an auxiliary equipment – classifier. It can classify and screen copper ore and release copper ore powder that meets the requirements.

3. Screening and classification: According to the size of the sieve surface, the material is divided into different particle size grades, which is often used to process materials with coarser particle size. According to the different settling speeds of particles in the medium (usually water), the materials are divided into different equal-fall grades, called classification, which is used for materials with smaller particle sizes. Screening and grading are to separate the materials with suitable particle size during the crushing process, or to divide the materials into different particle size grades and select them separately.

4. Ore washing process: Ore washing is required to prevent the mud in the mud-containing mineral raw materials from clogging the crushing and screening equipment. If the raw materials contain soluble useful or harmful components, they should also be washed. Washing can be done as well as in screening and grading equipment.