Sarah Garcia

MemberMeeting Tomorrow’s Production Targets in Low & Medium Seams

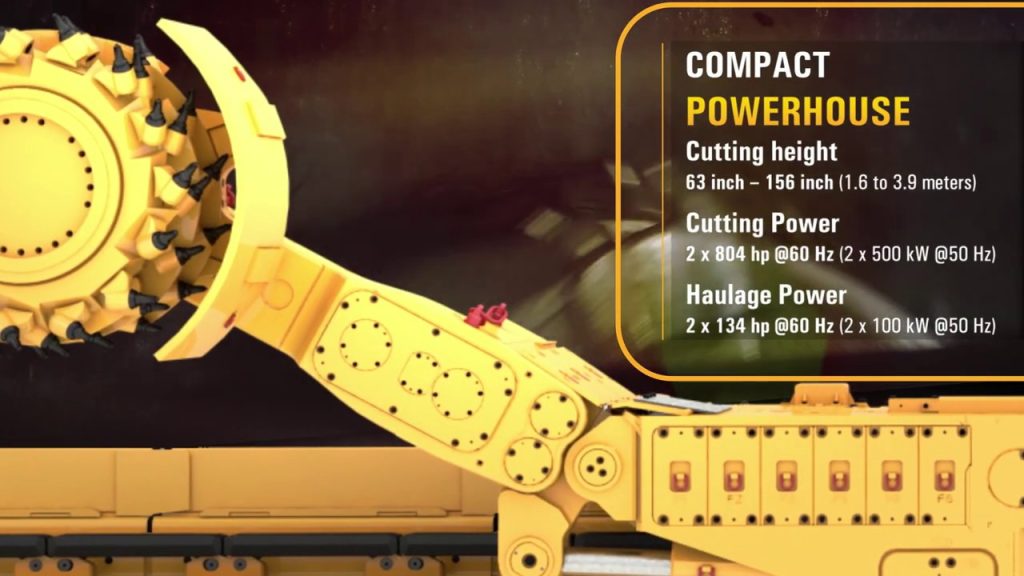

For low seam shearer applications, the most compact Cat solution yet will be there to deliver the results you expect: the new Cat EL1000. This latest addition to the successful range of Cat longwall shearers will cover seam heights from 63 to 156 inches (1.6 to 3.9 meters). With cutting power of 1600 hp (2…

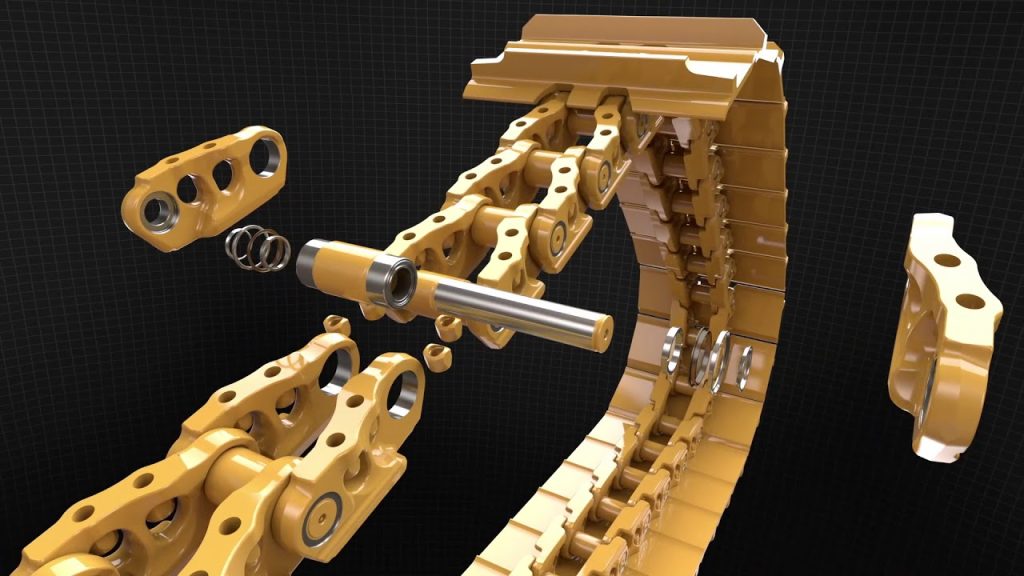

Cat HDXL extends your undercarriage life

See how the Cat HDXL can help extend your dozer undercarriage life. Source

The Cat® MEC500 Mobile Equipment Charger

A first of its kind for the mining industry, the Cat MEC500 Mobile Equipment Charger is a standalone fast charging system designed to charge quickly and safely wherever it’s needed. It can be towed, dragged or fork-lifted — eliminating the need for regular battery handling and swapping. And it can fully charge the Cat® R1700…

Cat® Track Drills Customer Interview Drill & Blast Contractor, JEMCO, featuring Jim McKeever

Why JEMCO chooses Cat® Track Drills: Versatility in applications, highly productive, easy to service, the Cat Rock Drill advantage, and cost savings that keeps JEMCO competitive. Source

What’s New in Underground Mining: Behind the Scenes with Caterpillar at MINExpo 2016

Get a behind-the-scenes look at the underground mining area of the Cat® MINExpo 2016 exhibit. Subject matter expert David Rea talks about our commitment to the underground mining industry, as well as the “must-see” products and solutions on display and how they can help you improve your bottom line. Source

Building a Mine: From Planning and Power to Machines and Support

When Stornoway’s Renard diamond mine began its production ramp-up in July 2016, it was ahead of schedule and under budget. Stornoway gives credit to the many partnerships that were essential to this achievement — from the local First Nations Cree community and government entities, to local construction crews, and to Caterpillar and Cat dealer Hewitt…

Improve Autonomous Mining Safety & Productivity | Caterpillar

http://catminestarsystem.com/articles/autonomous-trucks-driving-safety-and-productivity-improvements Operator safety tops the list of reasons to use autonomous mining technologies, but mine site that put these technologies to work have also seen benefits ranging from higher equipment utilization to less machine damage and increased productivity. In fact, some sites have experienced speed and efficiency increases that boost production by up to 25…

Cat® Rock Flow – Continuous Hard Rock Haulage System

The Cat® Rock Flow System animation shows Caterpillar’s continuous production system for block caving operations to deliver increases in productivity and safety at a lower cost. For more information visit: https://mining.cat.com/products/underground-mining/hard-rock/rock-flow-system Español – http://youtu.be/GcA01Rgr4Mw Source

Depoimentos: Cat® 6015B

Ouça diretamente das pessoas que usaram a Escavadeira Hidráulica de Mineração Cat® 6015B pela primeira vez. Source

Brake wear indicator kit for Cat 789C

Caterpillar offers a kit to retrofit your Cat 789C with brake wear indicators that greatly reduce inspection time for brake wear. Visit https://mining.cat.com/retrofit to learn more. Source