Seven Factors that Affect the Flotation Process Effect to Consider

The stirring of the slurry can promote the suspension of the ore particles and the uniform dispersion in the tank. It can promote the good dispersion of the air and make it evenly distributed in the tank. It can promote the air to strengthen the dissolution in the high pressure area in the tank, and strengthen the precipitation in the low pressure area, so as to cause a large number of active microbubbles.

Strengthening aeration and agitation is beneficial to flotation, but it should not be excessive, because excessive aeration and agitation will produce the following disadvantages: Promote the merger of air bubbles; Reduce the quality of concentrates; Increase power consumption; Increase the wear of various parts of the flotation machine; The volume of the pulp in the tank is reduced (this is because the volume of the tank is increased by the part occupied by the bubbles); Excessive stirring may also cause the ore particles attached to the bubbles to fall off.

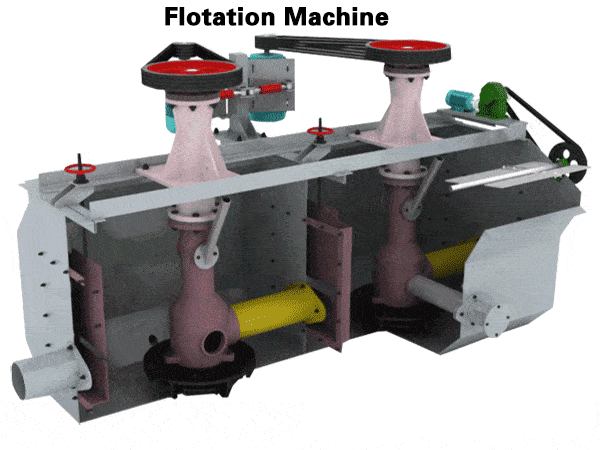

The optimum amount of aeration and agitation in production should be determined through experiments according to the type and structural characteristics of the flotation machine.